EXTERIOR FIRE RETARDANT COATING

Southwest Research Institute

ASTM E108 - UL790

| TEST | MATERIAL TESTED |

RESULTS |

|---|---|---|

| Spread of flame | Sprayed Shingles 5-year Weather (200 inches rain simulated) |

Class C |

| Burning Brand | ||

| Flying Brand | ||

| Intermittent Flame Exposure | ||

|

TECHNICAL DATA EXTERIOR CLASS C RATING |

|---|

PRODUCT DESCRIPTION: Aqueous Based Resin

| PRODUCT ANALYSIS | ||||

|---|---|---|---|---|

Total Solids |

33% | PH | 4.6 - 5.2 |

|

Weight per gallon |

9.4 lbs | Flash point | Non-Flammable |

|

Specific gravity |

1.104 | Color | Water clear at 78°F. - Slight haze at 50°F. or lower |

|

Volatability |

Non-Volatile | Solvents | Water(Contains no petroleum or derivatives of petroleum) |

|

Anti-Fungus |

excellent Resistance | Bacterial | Good Resistance |

|

Linear shrinkage |

None | Moisture Absorption | None |

|

Corrosive |

Mildly | Toxic | None (when dry) |

|

Insects, rodents, aspergilli And other types of molds |

Excellent resistance | Termites | Excellent resistance |

|

Preservative for wood |

None | Scrubability | 1000 cycles |

|

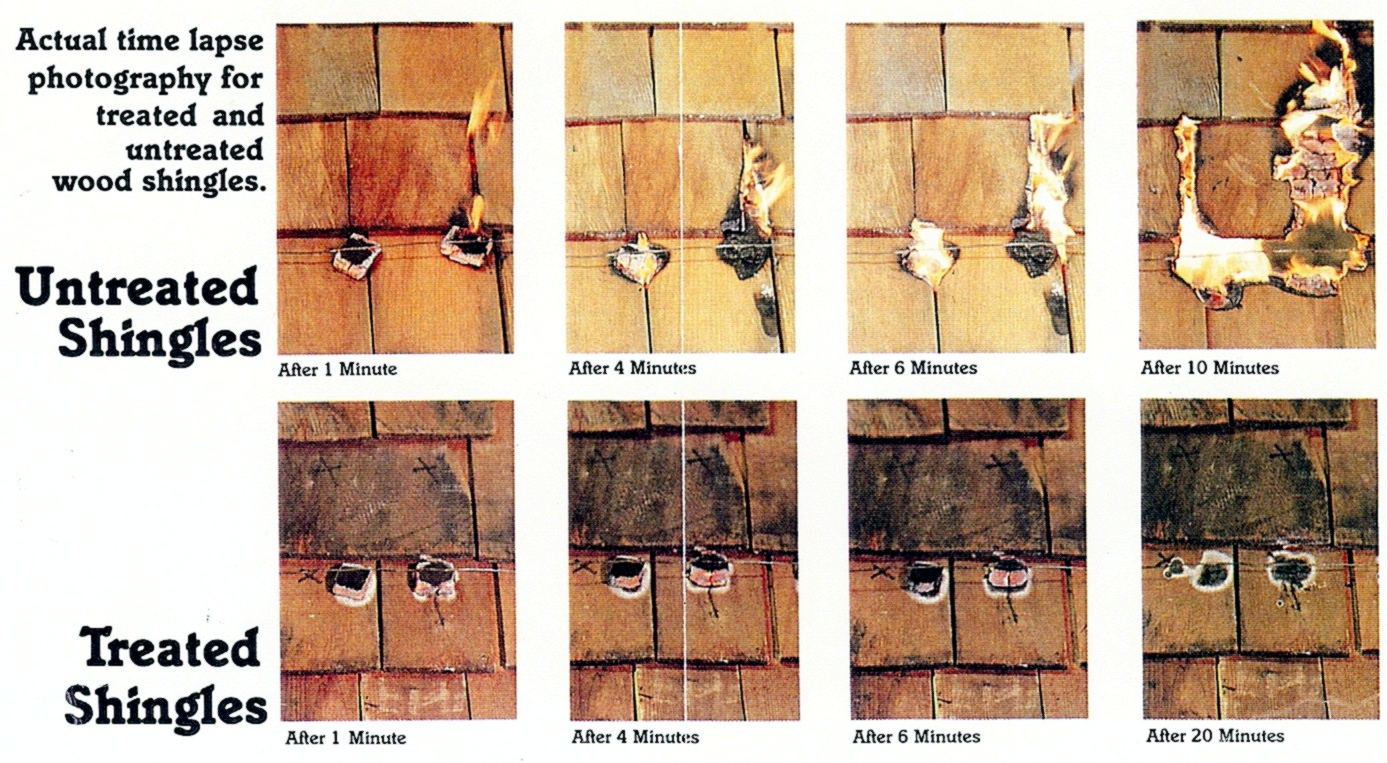

RECOMMENDED USE: Exterior Class C Rating

FLAME SAFE SHINGLE SAFE is a fire retardant coating and penetrant. It can be used on any type of wood or porous materials, such as:

| Wood Shingles | Cedar | Wood Siding |

| Redwood | Wood Fencing | Plywood |

| Taper sawn SYP-ACQ |

ENVIRONMENTAL REGULATION:

This product complies will U. S. Federal Regulations concerning the use of lead in paint and hydrocarbon emissions.

|

QUICK REFERENCE FOR APPLYING SHINGLE SAFE |

|---|

MATERIAL |

APPLICATION |

COVERAGE |

Exterior wood Wood Shingles and Shakes, wood siding. wood fencing

|

Pressure wash roof to remove all foreign substances (fungi, molds, mildew, etc.) Be sure surface is clean and dry before treating Apply with sprayer head held at 8 to 12 inches from surface. Treat all surface areas Do not expose treated area to moisture for 24 hours. Treat roofs by applying chemical to surface area and substructure area (attic), if possible |

110 sq. ft. per gallon |

WOOD ROOF SURFACES |

|

|---|

CAUTION:

Product must not freeze. It must not be thinned or diluted.

OVERSPRAY:

The overspray will not harm plants or animals. Spills can be flushed with water. A rag wetted with bleach and water mix will clean up spotting.

CLEAN UP PROCEDURE:

Airless Equipment.

1. Run clear water through the system until coating is flushed out. When minor sudsing on surface stops, the system is flushed.

2. Run bleach and water mix (1 part to 4 parts) through system as solvent for cleaning any residue.

3. Repeat Step 1 if any foaming occurs in Step 2.

4. Lubricate system as specified by equipment manufacturer to combat rusting.

If two or more applications are planned in the same day, the sprayer can be kept clean by running water through the system between applications.

Brushes/Rollers.

1. Clean immediately after use.

2. Wash thoroughly with bleach and water mix (1 part to 4 parts).

SAFETY FIRST

Use approved safety devices (ropes, belts, ridge hooks, ladder, etc.) When working on steep or high areas. Take EXTREME CARE not to step on wet treated area. Surface may be slick until dry.

It is good practice to wear respirator or mask and protect hands with rubber gloves when spraying any coating or chemical. When engineered air control is not feasible, use properly maintained and properly fitted NIOSH approved respirator for solvent vapors. A dusk mask does not provide protection against vapors.

If eye contact occurs, flood with water for fifteen (15) minutes and call a physician. KEEP OUT OF REACH OF CHILDREN. DO NOT TAKE INTERNALLY.

|

|---|